Here we’ll talk about designing your robot from scratch using first some paper and a pen and then onto some type of 3d design software and either printing the parts yourself or having a print shop print the parts for you as you need them.

Of course you could improvise and not produce the parts from scratch.

You could take a retail mannequin and cut it up and place linkages, motors and sensors and an arduino and program it to be semi autonmous.

You could take simple PVC tubing to make the arms/legs and do the same thing and then add a layer of foam and fake skin or simply put clothing on top of it if you are making a humanoid robot.

But lets keep talking about designing a robot with software.

But do keep in mind that you can’t tell on a computer screen how heavy and bulky a 5 foot robot could be.

Remember heavy robots can fall on and hurt people and they can break the fragile computer/electronics parts or finger and leg joints.

Some big robots have to rely not only on motors but also pulleys and belts to take the motion all the way through the length of an arm or a leg.

Large robots are said to need at least two things: high mechanical rigidity and some type of gyroscope to keep it stable on its feet (unless you are building a platform robot or a wheeled robot)

It can take hours to simply print a robot hand and an overnight print for an entire arm with some printers.

Now you can save a lot of time and energy by building a humanoid robot by modiying existing parts like a mannequin body or head or eyeballs and some moving servo or robot arms and head mechanisms from other robot toys or remote control airplanes and cars.

Some robot builders have used battery powered power drills to make legs move on a robot and even motors from a dishwasher or vacuum cleaner for some parts.

But for now we’ll talk about how to get started in 3D printing with main brands of printers and software, the files involved like stl and design issues like what type of plastic to use or maybe not plastic at all.

Serious professional robot builders usually insist that all metal servos with metal gears are the only way to go and that the servos in the head and elsewhere must be mounted with strong aluminum frames and not bendable 3d printed plastic iones in places like the eye, mouth or limbs.

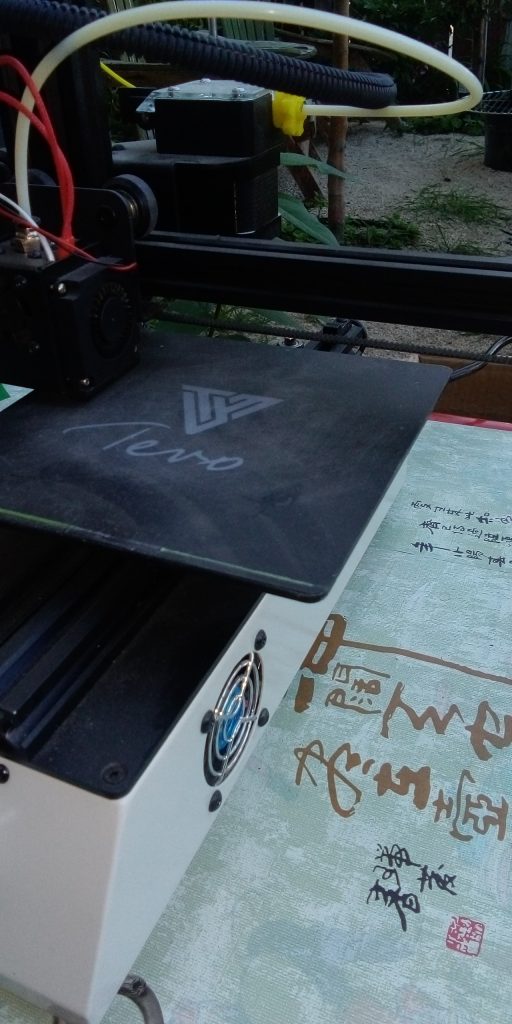

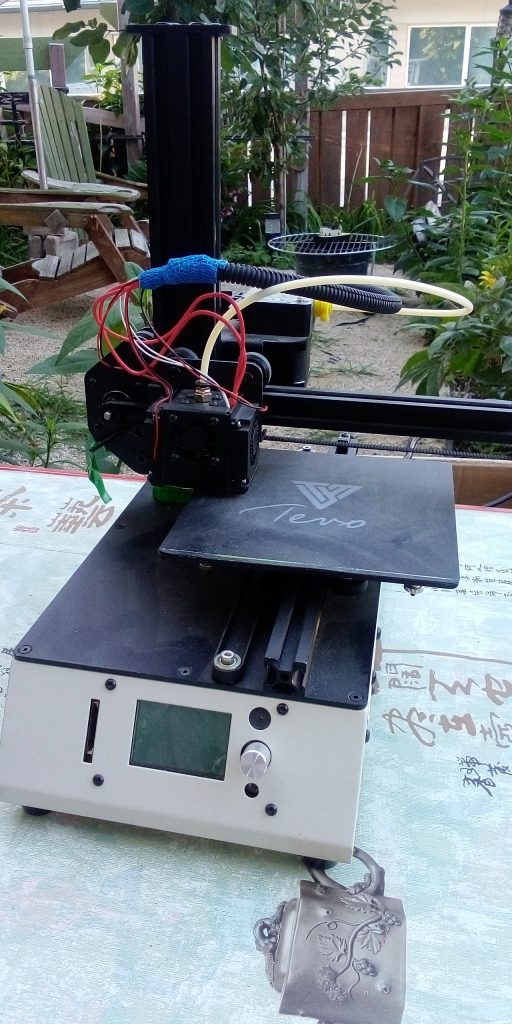

3D printing in 2021 has suddenly become almost as common place as regular ink jet printing was since the price to buy one can be as low as a few hundred dollars!

We’ll describe some of the differences in the 3 prices shortly.

But first what is 3d printing and why would you want to do it?

Its basically a way to design objects in a computer design program and then print them out usually layer by layer on a 3d printing machine.

Most of us first heard about 3d printing technology about 20 years ago when scientists said they were able to print tiny human tissue or heart valves using million dollar 3d printing equipment.

Today, one could print similar plastic heart valves with a free program like Blender and a used $50 MakerBot 3d printer!

The first 3d printer was formally invented by Charles Hull in 1988 and many improvements have been made since with over a dozen name brands to choose from.

Yes you can print a 3d object like an apple in metal, plastic or almost any material..the printers under $2,000 will generally only print using plastic.

If you were to watch a person create something it with a 3d printer, it would be in these stages

- – You would either design your object in a program like Blender or get a predesigned object and use that file which is called an STL file

- – You may need to use another program like Replicator G to slice up this file into thin layers so it can print properly.

- then you would plug in a USB stick into the printer containing your design as a 3d STL

- – you would have already adjusted the printer and leveled it and prepped the print bed if its not a heated bed

– the 3d printer would then start to buzz and go back and forth melting a roll of plastic (fillament) which looks like weedeater line that it has at the back and it woiuld slowly form the first layer of the object and then another and another until it is done in maybe !0 minutes or a few hours. (called additive ) - – you should watch the process for a few minutes to make sure that the print head doesn’t get stuck or something goes crooked

– you pull the object off the print platform and let it cool off and snap off the excess pieces and you are done . - – you may have to sand it down or paint it unless you chose a color that you liked and you may have to glue pieces together if you for example only printed out one finger of an entire hand

Okay lets explain the technology now a bit more.

3d printers use a process called additive layer manufacturing.

You buy rolls of one of the special types of plastic called fillament and feed it on the machine.

You probably have to make a few adjustments on your printer like level it if you haven’t used it for along while and perhaps make sure that the nozzle isn’t clogged.

You may have to clean the bed or if your printer doesn’t have a heated bed then you may want to put glue on the bed or masking tape so that your formed model won’t slip.

When the machine starts, it heats it up thru the part of the machine called the extruder.

The melted blob is put onto a metal plate and the 3d printer head moves around laying down layer after layer of plastic until the object is finished.

If your object gets too high you may need to prop it up so it doesn’t fall over or simply design your object in separate pieces and put them together separately.

There is a lot of learning and skill to get it totally right but anyone can output a simple blob of plastic to simply see how the machine works.

In fact most machines will give you some sample 3d prints to do and they will usually come out perfectly and make you a real 3d printer believer.

Yes these machines are burning plastic and some is worse than others and so you should have ventilation and some machines are enclosed which is safer at least so nobody might accidently touch a hot sur

You can use various 3d design programs if you don’t simply want to print out a completed design on a site like Thingiverse.com

Some popular 3d design programs include these ones:

Blender

Sketchup

Autodesk (basic)

Most large city libraries now have 3d printers and advanced technology like this for the public to use when the libraries are open to the public.

Otherwise most larger cities set up what is called a makerspace, which are informal groups of people who get together and share a 3d printer and resources for a minimal membership fee and perhaps some volunteer comitment time.

.