Lets talk about the basic mechanics behind gears and gear boxes as they relate to making robots move and all the terms that get thrown around like gear ratios, torque, bevel and helical gears and more.

Everyday, we see these circular spinning gears on bicycles and cuckoo clocks and most of us don’t know why there are more teeth on some gears than others and why you sometimes you see 3 or 4 gears touching each other instead of just 1.

Well, basically, gears called “simple machines” and are used to transfer rotational motion from one part of a machine to another and at the same time can either change the speed, direction or the torque that is needed by the device or robot arm or leg.

We’ve all seen small or large DC motors spinning at incredibly fast speeds and we need a way to slow it down and increase its power so it can move a robots arm up and down slowly with some strength.

It just so happens that if you add a larger gear to the small spinning motors shaft that the larger gear will move slower and have more power or torque than what came straight out of the motors tiny shaft.

So every gear has a certain number of teethand when you have several gears touching each other you can calculate the gear ratio by dividing the number of teeth in the driven gear by the number of teeth in the drive gear to get a number like 4:3.

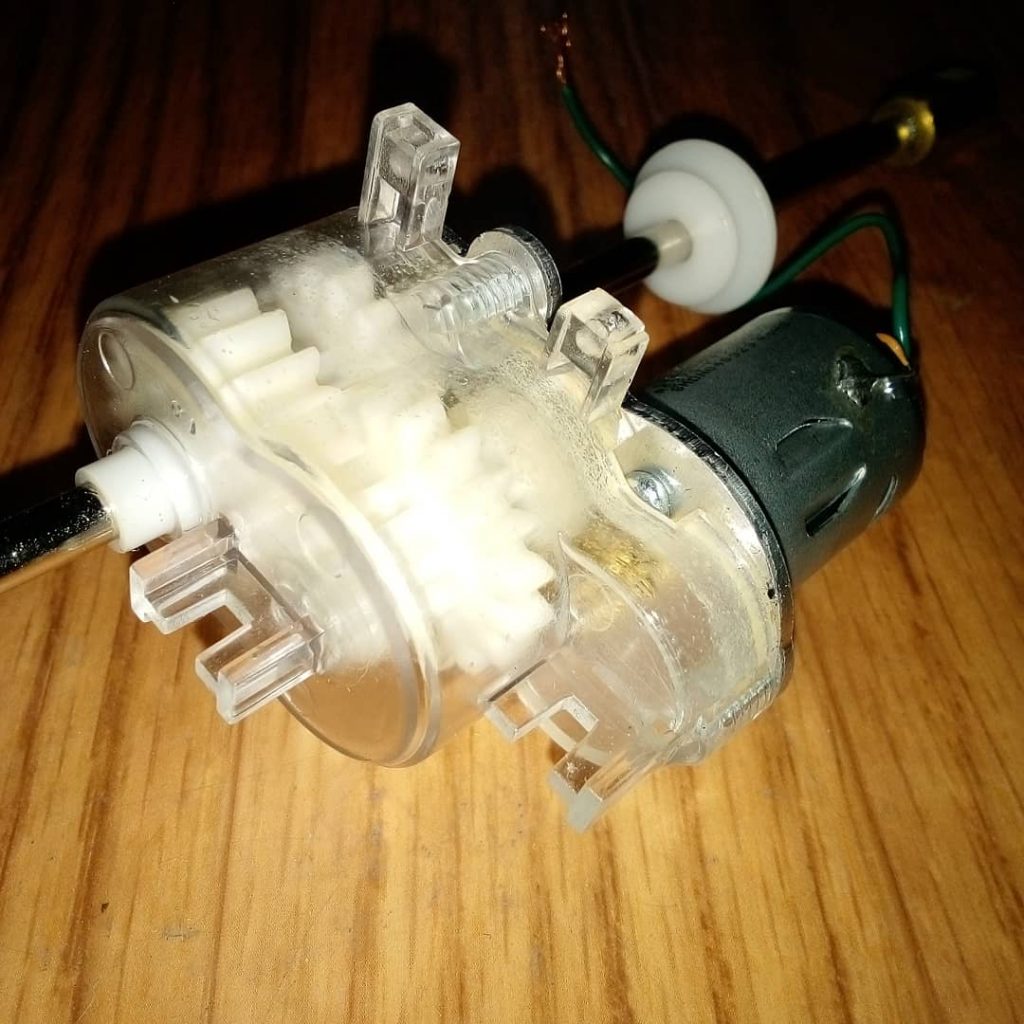

Several gears can then be put into a box called the gear box which is also what you have in a car transmission and then a standard transmission would have a clutch to engage the gears slowly so they wouldn’t just crash into each other and break all the gear teeth.

Now A servo motor usually has several parts including the motor, a gear box, a potentiometer, control board and an output spinning shaft.

Some cheap plastic $5 servo motors can split their gears easily and stop moving your robots eyeballs or perhaps finger. You would use higher power servos for robot parts that needed more power like arms and legs.

So lets go back and explain what a gear is used for and why some have more teeth than others and why some are made at an angle as in a bevel gear etc.

We know that gears transfer power in our robots and sometimes we need to transfer power a longer distance in an arm or leg so we may need to connect several gears with chains or belts like in a bicycle.

If you look at some of the most advanced and expensive robot heads like the Mesmer robots at Engineered Arts you can see you can chains attached to expensive metal motors. Cheaper robots try to connect a servo directly to a robots eyeball moving linkages with a few inches of plastic.

If you have seen a watch or a cuckoo clock then you have seen a handful of gears that touch each other and cause some kind of movement.

Now in a robot you are usually concerned about the gears in the motor but you also may need to use gears where there are joints like in arms and legs.

We use the terms gears and gear boxes.

Gears are usually round with a hole in the center and certain number of teeth around it.

A gearbox usually refers to the gears that are in a small box attached to a motor which causes some variation in how fast the motor spins.

Most motors spin too fast to be of much use in a robot so you attach a series of gears to slow down the speed of the motors effects and increase its turning power or what is called its torque.

Gears always work in pairs and the one gear must have its teeth mesh with the one it is touching. The first gear will turn in one directrion while the gear it touches will spin in another direction and it will now result in a slower speed according to some mathematical calculation.

Now most toy robots will eventually fail because the cheap plastic gears eventually chip some teeth from age or from overuse.

You can repair some of these unless the gears are in the gearbox and its not easy or practical to fix it as opposed to buying a new servo.

If you go on youtube you can watch the Gemmy animatronics repair videos by GMA and they show how to replace gears in the toys head or shoulders or hip etc.

In the head of some of the Gemmy’s there are a handful of big gears that rotate as well as the main tiny gear which attaches directly onto the motor shaft.

The problem with these 20 year old toys is that the plastic gear “splits” and needs to be replaced so that it will properly mesh and turn the other gears. there are 3 choices or sizes of gear that go directly onto the motor. (8 tooth or 9 or 10 tooth) These gears can be found on Amazon.

Anyone with a 3d printer can print pretty well any gear type in the world now although it will be plastic unless you take your request to a company which can print metal gears.

We need to talk about plastic versus quality metal gears and the number of teeth it has and what to do if your robots gears break and the whole thing catches fire because their wasn’t cut enough ventilation in the body suit or a fuse to cut out the circuit before it overheated or you used the wrong power supply or circuitry.

Now technically there are a handful of types of gears and they have names like:

- spur gears (simplest gear but noisier than planetary gears)

- helical gears (gear teeth are at an angle)

- bevel gears

- worm gears

- planetary gears

- rack and pinion gears

- sun and planet (used in old fashion steam engine)

- harmonic

- cycloidal

Spur gears have straight teeth while helical gears have teeth set at an angle. You can have one or several rows o teeth on a helical gear pattern.

Bevel gears mesh together at a right angle to send power between the intersecting axles.

Worm gears are like a screw that spins around an axle.

Planetary gears are used in car transmissions whjile rack and pinion gears are used in car steering mechanisms.

James Bruton, YouTube robot builder has this excellent video where he is shown 3d printing gears for his Robotx robot. He has several 100 RPM motors attached in one case to a worm gear and the other to a spur gear. It is amazing to watch his bevelled gears working with the robot arm to give it smooth movement.https://www.youtube.com/watch?v=lo5Ldd5gcBw&t=279s

Now one of the first repairs needed to a robot toy that stops working other than the batteries being dead or corroded is to check the condition of the gears.

Usually a gear has one or more of its teeth chipped or missing or it is missing entirely or mayb its someting completely different but its easy to blame the gears.

Most toy robot gears are plastic so it is expected that with heavy play by the child, that some gears will eventually fail.

The possibility of a gear failing is why you need to incorporate an auto shut off or fuse turn off device in the event that the robots start to act weird or starts to smoke.

The Gemmy 1980s dancing Santa often had a problem with the gears since the Santa was quite heavy (20 pounds) and sometimes the weight would cause problems with the circuit board.’

If you go on youtube you can watch the Gemmy animatronics repair videos by GMA and they show how to replace gears in the toys head or shoulders or hip etc.

In the neck area of some of the Gemmy’s there are a handful of big gears that rotate as well and touch the main tiny gear which attaches directly onto the motor shaft.

The problem with these 20 year old toys is that this tiny plastic gear attached directly to the motor, “splits” and needs to be replaced so that it will properly mesh and turn the other gears. There are 3 sizes of gears to choose from for the various Gemmy characters. (8 tooth or 9 or 10 tooth) These gears can be found on Amazon.

Anyone with a 3d printer can print pretty well any gear type in the world now although it will be plastic unless you take your request to a company which can print metal gears.

There are also belts in some of these toys that break and they can be found in home repair stores.

Lets talk about the Lego sets for a bit here and their gears.

Back in the Lego Mindstorm RCX day a robot builder hobbyist by the name of Eric Sophie created a Lego 50 inch tall Robot named Jamocklaquat with 41 RIS Lego motors with 12 programmable RCX bricks.https://brickshelf.com/cgi-bin/gallery.cgi?i=822428

Gears can also have chains like from a bicycle or belts to extend the length of whatever needs to move.

Bearings are tiny metal balls that are packed tightly and ususally greased to make a smoother movement with mechanical parts like the neck and head of a robot or its waist.

Bearings are also used to take the weight of a wheeled shaft off the motor shaft.